I’ve encountered stories around the internet that portend to tell the story of how the Ten-Tec RX-340 Receiver came to be. I have to chuckle at the effort put into fiction. Honestly, the true story about how this radio came to be is interesting enough without the need to make it up.

Because the RX-340 is closely related to the RX-330 receivers it could be assumed that the RX-340 is derived from those products. The reality is, a product like the RX-340 was under development before the RX-330.

In the late 1980’s and early 1990’s shortwave listening was still a significant market and monitoring of the HF spectrum was being done extensively by hobbyists and government entities alike. And as in most product markets there are multiple levels of business… base, mid-level and top-tier, which encompasses consumer, commercial & government of all types. To be sure, Ten-Tec was not new to shortwave receivers, having previously designed and manufactured an analog radio for the Navy, the model SP-325. The SP indicating it was for the Shore Patrol.

In 1991 we started looking again at designing a shortwave radio that might be attractive to high-end consumer, commercial and government users. At that time, the leader in the high-end market was the Watkins-Johnson, WJ-8711. WJ also produced a black box version, the 8712, which had no front panel.

In late 1991, we were just beginning to play with Digital Signal Processing (DSP) and became interested in creating a radio that would use DSP to perform traditional analog functions At the time there wasn’t a great deal of information available on how to do that. So we set out to develop our methods and algorithms from scratch. It was slow at first but once we had developed the demodulator algorithms we felt confident we could design a DSP radio with great performance and at a significant lower bill-of-material (BOM) cost than if it were an analog design.

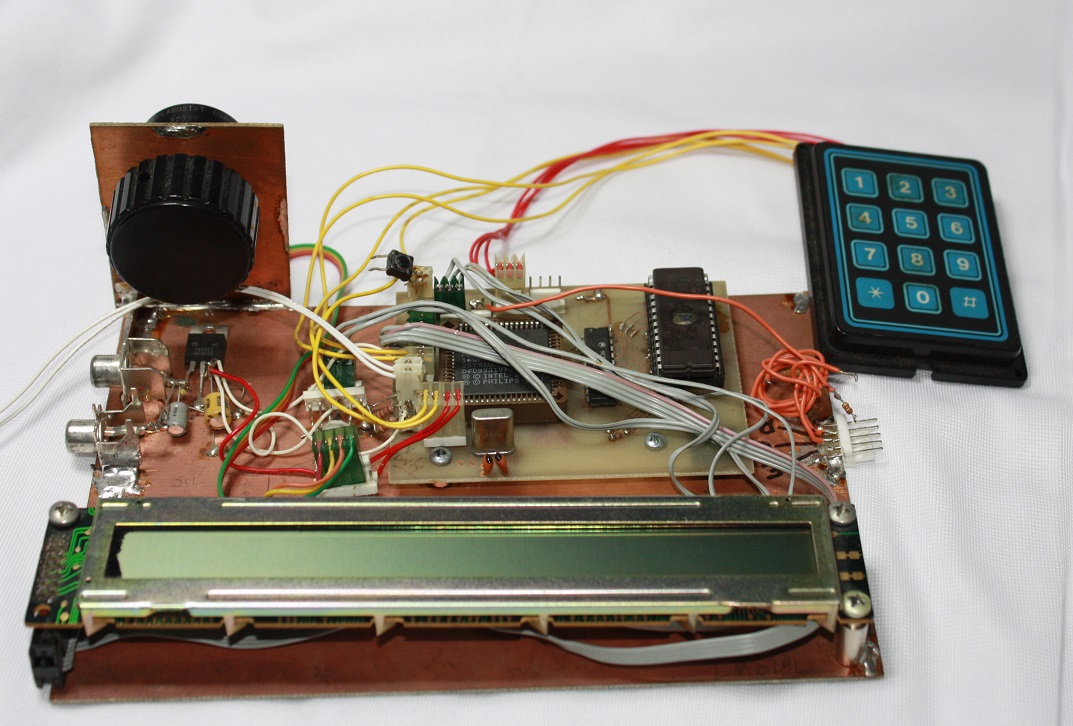

That radio, which would eventually birth the RX-340, was internally referred to as the “DSP Monitor Receiver”, and was assigned the model number RX-336. In addition to DSP performing many of the analog functions, the radio would feature a removable and remotable front panel assembly. The radio without the front panel would be designated model RX-335. In early development, the front panel was a simple Encoder/Display with multi-layered menus as our focus was on the RF/DSP hardware which was the critical element. Much later, a more elaborate panel would be designed for the RX-340.